Operations Management - The day-to-day running of a company

Ultimately, the nature of how operations management is carried out in an organization depends greatly on the nature of products or services, for example, retail, service, manufacturing, wholesale, etc. Whatever the system or organization, the functions of operations management are always the same: (1) designing, (2) planning, (3) organizing, (4) directing, and (5) controlling. Management establishes the goals and objectives of the organization and plans how to attain them. Basically operations is about:

- Designing services, products and delivery systems.

- Managing and controlling the operations system.

- Continuously finding ways to improve its operations.

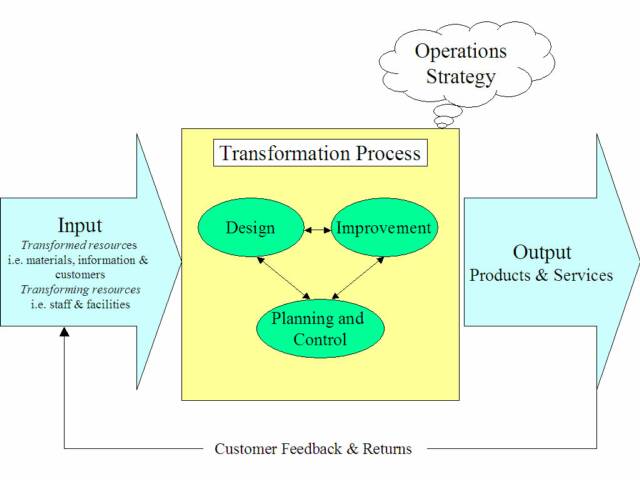

Every organization, be it a product or service organization, transforms certain inputs into outputs. The quality of these inputs is to be monitored regularly to get the desired output. The general model of operations management, which is a transformation process, would look like this transformation model:

A transformation process is any activity or group of activities that takes one or more inputs, transforms and adds value to them, and provides outputs for customers or clients. Transformation processes include:

- Changes in the physical characteristics of materials or customers.

- Changes in the location of materials, information or customers.

- Changes in the ownership of materials or information.

- Storage or accommodation of materials, information or customers.

- Changes in the purpose or form of information.

- Changes in the physiological or psychological state of customers.

In many cases, all three types of transforming input resources, which are materials, information and customers, are transformed by the same organization. For example, withdrawing money from a bank account involves the account information, materials such as dollar bills and checks, and the customer.

A useful way of categorizing different types of transformation within operations management is into:

- Manufacturing – This is the producing of goods and physical creation of products, such as cars, and the running of the factory, which would include purchasing materials and supplies. There would also be inventory responsibilities.

- Transport – This is the movement of materials or customers, such as a taxi service or trucking fleet.

- Supply – This would be the change in ownership of goods, such as a retail store, supermarket, etc.

- Service – This could be considered the treatment of customers or the storage of materials, such as the back office duties of providing customer service in a call center, or warehouses to store goods. Part of service would also be a possible output of customer feedback and return of goods.

Ensuring products are made; inventoried, shipped, received, repaired, and all the while managing the company’s facilities, are considered part of operations management. In some cases, providing customer service functions like support or care, are considered part of operations, although sometimes customer service might be associated with sales, or even an entity unto itself.

Operations Management makes sure the business is running efficiently including employee productivity, delivery, cost control, and quality. The analyzing of processes using both mathematical and scientific data is crucial for optimal performance. With process analysis, you can identify improvements, that will turn into cost savings, which can then be passed on to the customer, streamline the company’s infrastructure, and streamline inventory and supply chain issues. Some typical operating decisions would be:

- How much should you invest in developing new products?

- How much staff and space is needed?

- How do you determine the best buys on expensive items and equipment?

- What are the hours of operation?

- How long should a project take to complete?

- How much inventory is needed?

- How will the products be shipped?

- How will customer satisfaction be measured?

- How will the operating systems, workstations, and physical plant be designed?

- What are the processes and procedures used to ensure smooth operations?

- How to ensure quality and needed quantity of goods or services?

The examples just covered are only a few of the types of decisions an operations manager needs to make. Fortunately, there are many tools like flow charts, project task sheets, and cost/expense tools to help with making these types of decisions in all areas involved within operations management.

Operations managers are usually stereotyped as a plant manager in charge of a factory, however, there are also quality managers, production and inventory control managers, and line supervisors. In service industries, managers in hotels, restaurants, hospitals, banks and stores are operations managers as well. In the not-for-profit sector, the manager of a charity store, nursing home, and day center for older people, are all also considered operations managers.